| |

| |

- Description

- Features

- Benefits

- Modes of Operation

- Optional Software

| |

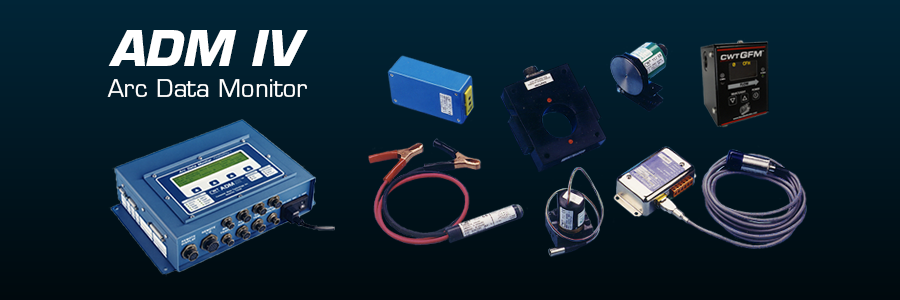

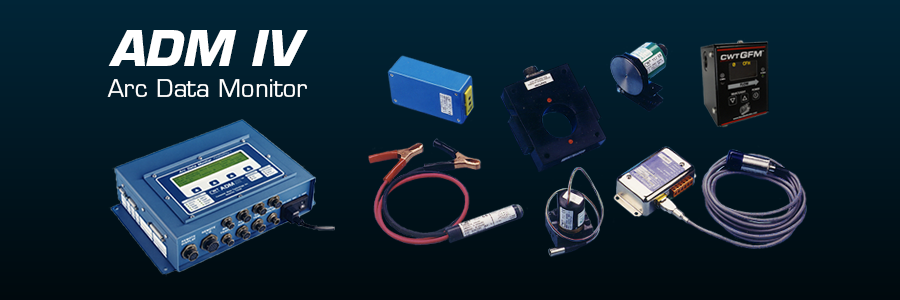

This user friendly, ADM IV Arc Data Monitor

can be easily configured to fulfill the requirements of

any end users needs. This

device can be employed as a stand-alone unit using the "Remote Display" to configure the system and view

the results or it can be linked to a PC to accomplish

the same

task.

The

modular design and compact size of the new ADM IV

and the fact that it is software configurable permits each

user to design and implement their own unique system to

achieve the desired end results. Internal

memory permits information to be saved at the job site and

downloaded to a printer or personal computer at a more convenient

time and location.

The

ADM IV is a rugged, versatile and cost effective

tool that can be arrayed in single and multiple arc configurations. It is a versatile quality control

device that is capable of assuring that all of your arc

welding parameters meet or exceed "ISO-9000",

"QS-9000" standards and your Statistical Process

Control (SPC) requirements.

The

Windows compatible ADMSTAT Plus software provides

a mechanism that permits additional data storage and further

analysis of collected data. |

| |

| |

|

|

Personal computer interface |

|

Networking capability |

|

64 user definable weld schedules |

|

Plug-in sensors and remote pendant |

|

Monitoring of all welding process data including pulse parameters |

|

Compact, versatile, rugged and lightweight design |

|

Two spare analog inputs |

| |

|

|

| |

| |

|

|

Facilitates off-line programming and data collection |

|

Network

multiple ADMs™ to a single computer |

|

Simplified installation and upgrade capability |

|

Provides

documentation and data trend analysis relating to the welding

process on a non-invasive basis |

|

Easily

installed in new or existing applications |

|

Provides

versatility / flexibility for additional parameter inputs |

| |

|

|

| |

Data

Monitoring - The portable ADM tests actual weld parameter

data and compares it to upper and lower control limits for

each parameter. When a fault condition is encountered, the

system sets an internal alarm relay, which can be used to

shut down the welding system or activate an external alarm.

Data

Logging - This mode is for data collection only. Welding

parameter data can be dumped to an external printer for

hard copy printout and fault analysis or to a compatible

personal computer using ADMSTAT Plus

software for data storage and analysis. |

| |

Our Windows® based ADMSTAT Plus™ program

was designed and developed specifically for use with the ADM IV

Arc Data Monitor. ADMSTAT Plus is compatible with Windows®

XP Service Pack 2 or later operating systems.

The real-time collection and display

of the welding data is accomplished using the proprietary high-speed

serial communication protocol with the ADM IV™. Single and

multiple welds can be gathered, arranged and identified by weld

schedule using the appropriate weld collect mode and by employing

the graph functions, the user can view and analyze the stored welding

data.

Also provided is an ASCII terminal program used to configure

or query the current status of a specific value, mode or function

of the ADM IV. |

| |

|

|

|

| |

Product Specifications |

|

- Sensor Limits

- Mechanical

- Electrical

| |

| Arc Voltage |

0-100

Volts +/- 1% (AC or DC) 0.1Volt Resolution |

| Arc Current |

0-1000

Amps +/- 1% (AC or DC) 1 Amp Resolution |

| Travel Speed |

1-100

IPM (.4 - 42mm/s) +/- 3% .1 IPM (.04mm/s) Resolution |

| Wire Speed |

10-1000

IPM (4.2 - 423mm/s) +/- 3% 1 IPM (.4mm/s) Resolution |

| Gas Flow |

5-255

SCFH (2-120 LPM) +/- 3% 1 SCFH (1 LPM) Resolution, 50 PSIA

(344 KPA) Maximum Operation Pressure |

| Temperature |

Range,

Resolution and Accuracy Depend on Sensor Used. Consult

Factory for Options. |

|

| |

| Dimensions |

3"

High 8.5" Wide 11" Long (76mm H x 165mm W x 280mm L) |

| Weight |

9.5

lbs. (4.3kg) |

|

| |

| Power Requirements |

115

vac or 220 vac 50/60 Hz @ 1 amp |

| Communications |

RS-232-C

Port , Parallel Printer Interface, RS-422 Network Port |

| Interface |

8-24

vdc input, 8 user definable relay outputs |

|

|

|

| |

|

|

| To see the list of Arc Data Monitor Products, press the link below. |

|

| SEE SYSTEM PARTS |

|

|

|

| Please disable browser pop-up blockers for documents on cweldtech.com to allow PDF files. |

|

|

| Note - All documents are in an Adobe PDF file format. |

|

|

| Press to enter download area for Autocad DXF drawing format. |

|

|